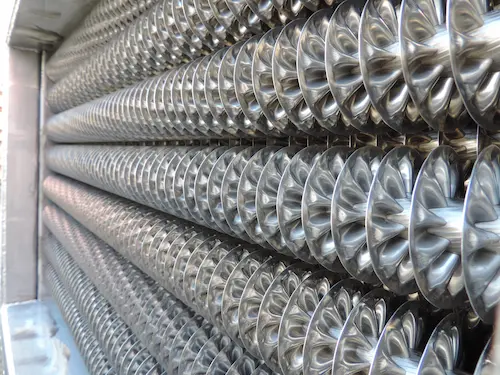

Spiral Tube Heat Exchangers

Spiral tube heat exchangers are the ideal choice when the process air is dirty, operating temperatures are very high, or when special materials or configurations are required.

Thanks to their mechanical robustness and great design flexibility, they are used across a wide range of industrial applications: process plants, ovens and drying lines, high-temperature flue gas heat recovery, cryogenic applications, and severe-duty air-to-air systems.

Versions with wrapped, interlocked, or continuously welded fins are available, each designed to maximize strength, reliability, and performance under the most critical conditions.

Key Features

Maximum dimensions

Typical tube diameters from 5/8” to 2”

Fin height: 10–25 mm

Fully customizable lengths and configurations according to plant requirements

Modular construction possible for large heat transfer surfaces

Materials

Fins

Aluminum

Copper

Carbon steel

Galvanized steel

Stainless steel (304/316)

Variable thickness to ensure strength and durability even above 450°C

Tubes

Carbon steel

Stainless steel

Copper

CuNi (on request)

Special materials for high-temperature or corrosive processes

Available Geometries

Wrapped, interlocked, or continuously welded fins

Interlocked or continuously welded versions, combined with suitable materials, allow operating temperatures > 450°C

Tube rows arranged in-line or staggered

Geometry optimized according to fluid, temperature, and mechanical requirements

Options and accessories

Cylindrical or domed welded headers, or inspection-capable

Anti-corrosion treatments

Custom frames for installation in complex plants

Compliance with major pressure codes possible

Guaranteed Performance

Our spiral tube heat exchangers are designed to operate under extreme conditions, ensuring maximum efficiency and long-term stability:

Mechanical design compliant with ASME VIII Div.1/Div.2, EN 13445, AD 2000, or other client-specified standards

High mechanical strength and long service life in demanding environments

Wide operating range: from high-temperature applications (>450°C) to cryogenic processes (-196°C)

Thermal and mechanical optimization through dedicated calculations and internal validations

Heat Exchangers for Industrial Applications

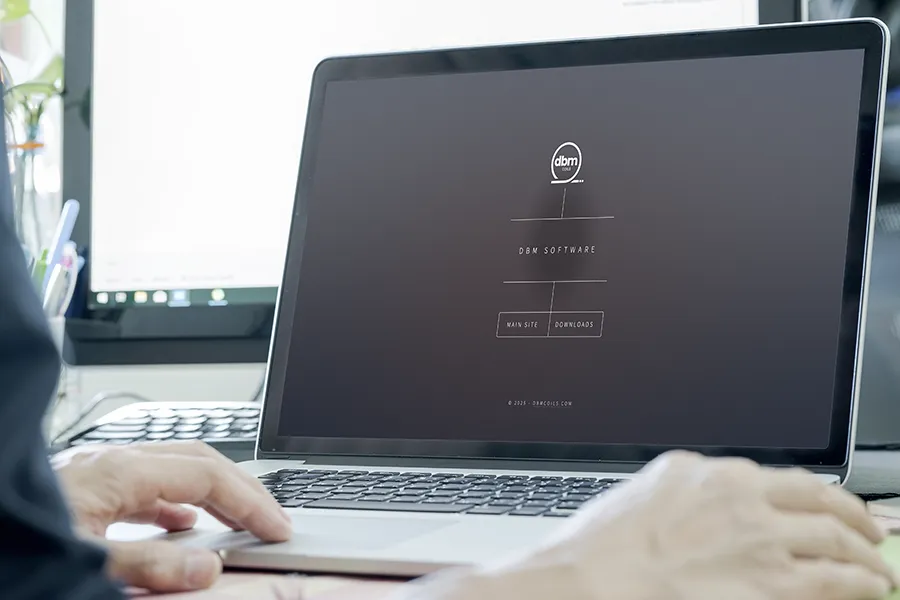

Selection software

DBM software allows rapid selection of spiral tube heat exchangers configured according to the specific requirements of your industrial application:

Thermal calculations based on experimental data

Dedicated parameters for high-temperature or dusty environments

Automatic selection of materials, thicknesses, and fin geometries

Available as standalone or DLL version for integration into client software

Want to learn more or have a specific project?

Our technical office will assist you in configuring the spiral tube heat exchanger best suited to your application.