High-Efficiency Energy Recovery Systems

Our finned pack heat exchangers for energy recovery systems are designed to ensure maximum heat exchange efficiency, thanks to a special circuit configuration that guarantees true counterflow operation.

This design maximizes the logarithmic ΔT between the two fluids and achieves performance levels unattainable with traditional cross-flow solutions.

The system is fully ventable and drainable, allowing for reduced installation and maintenance times.

It is the ideal solution for Air Handling Units (AHUs) that must comply with European energy efficiency requirements and ErP directives.

Key Features

Maximum dimensions

Finned length up to 14 meters

Height and depth variable depending on geometry and specific application

Materials

Fins

Aluminum

Pre-painted aluminum

Magnesium aluminum

Hydro aluminum fin

Copper

Stainless steel (304/316)

Tubes

Copper

Tinned copper

Stainless steel

CuNi 90/10 for demanding applications or corrosive exhaust air

Special materials on request

Available geometries

P25, P3012, P40

Sinusoidal fin profiles oriented parallel to airflow to minimize pressure drop

Circuits designed to maximize counterflow operation and efficiency according to EN 308

Options and accessories

Hygienic executions compliant with VDI 6022

Anti-corrosion treatments

Sectional design for easier transport and installation

Fully stainless steel versions

Guaranteed performance

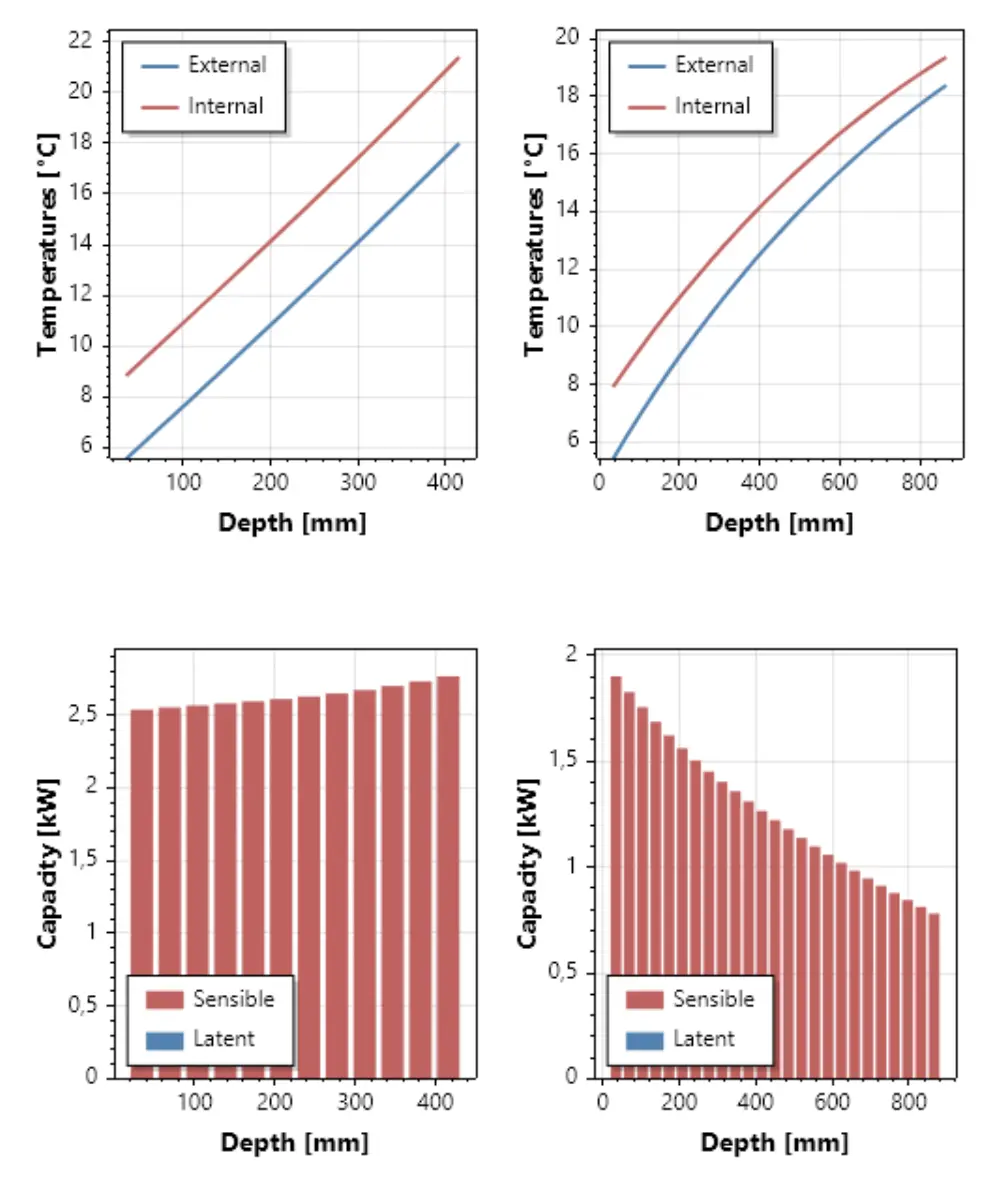

Our energy recovery systems achieve 68% efficiency according to EN 308, regardless of the number of rows or geometry used.

This performance is made possible by advanced circuit design, optimized flow distribution, and dedicated fin profiles.

Compliance with European ErP Directive (Energy Related Products)

Performance validated through internal experimental tests

Possibility of joint validation and comparative testing with the client

Reduced air-side pressure drop thanks to dedicated fin profiles

Higher efficiency compared to traditional cross-flow configurations

The images show the heat transfer by individual rows in counterflow as a function of the temperature difference between the two fluids. On the left, flow and temperatures are optimized, achieving 68% efficiency with 14 rows. On the right, a non-optimal situation requires double the surface area for the same process.

Heat exchangers for industrial applications

Selection software

DBM provides proprietary selection software, used by designers and engineers worldwide, to ensure maximum accuracy in selecting the right heat exchanger:

Advanced thermal calculation based on experimental data

Rapid selection of geometry and optimal configuration

Standalone version and DLL for integration into client software

Continuous updates based on internal laboratory results

Want to learn more or have a specific project?

Our technical office will support you in configuring the heat exchanger most suitable for your application.